|

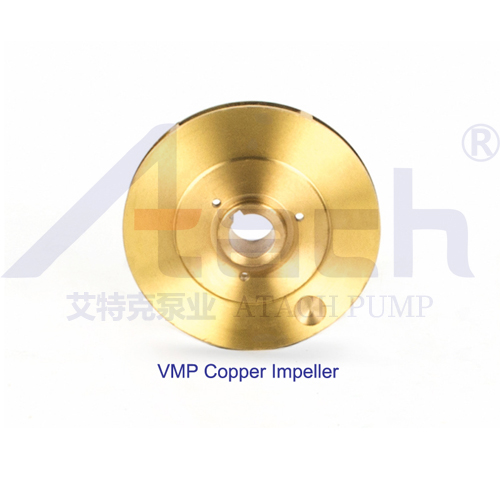

Why are bronze impellers widely used in seawater or brine media ?

Many of ATACH's customers may ask why stainless steel 304 is often not recommended for seawater or media with high salt (chloride ions) content, but duplex steel 2205/2507 impeller or bronze impeller is more recommended? Now we elaborate on this issue as follows: Bronze impellers are widely used in seawater or brine media, mainly due to their excellent corrosion resistance, wear resistance and mechanical properties. The following are the specific reasons: Corrosion resistance Bronze (a copper-tin alloy) can form a stable protective film in seawater or salt water, effectively resisting the erosion of chloride ions. Its tin content (5%-10%) further enhances the resistance to dezincification corrosion, especially performing exceptionally well in environments with high flow rates or suspended solids. Wear resistance The anti-erosion and corrosion performance of bronze is superior to that of stainless steel and cast iron, making it suitable for dynamic friction scenarios. For instance, aluminum bronze can reduce vibration and noise in ship propulsion systems and extend the service life of equipment. Mechanical properties Bronze has a high tensile strength and thermal conductivity, which can adapt to the low-temperature environment of seawater and reduce the risk of stress corrosion cracking at the same time. Copper-nickel alloys (such as CW352H) further enhance strength and corrosion resistance, but they are relatively expensive. Application scenarios It is commonly used in highly corrosive environments such as seawater desalination, condensers, and sea access systems, especially showing stable performance in sea areas with flow rates exceeding 3m/s or high sand content. |